Specifications

- Feeding Method :

– Electronic Mechanical & Pneumatic systems

- Feeding time :

– 0.5 ~ 0.6 Seconds - Electric Spec. :

– 50/60HzDualCycle

– 100V/240VDualVoltage

– SMPS Controlled

Button type

- Button Hole :

– 2 & 4 Holes- Standard, 3 Holes- Optional - Button Dia :

– 8~30 mm** - Button Tickness :

– 1.0~8.0 mm**

Application

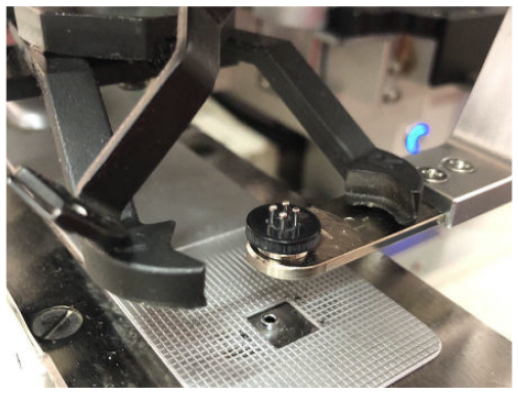

- This robot mechansism device is used to feed the buttons to the button clamp on the button sewing machine.

- Operator no need to align the holes of button.

- With its increased feeding speed, the sewing machine head speed can be used upto maximum, which results in higher productivity. Using this device a beginner shows double productivity than skilled operaters.

- Special button machine work clamp is provided along with BK-17 as per machine make.

- Transfer pin of different sizes provided with BK-17 as standard accessories.

Features

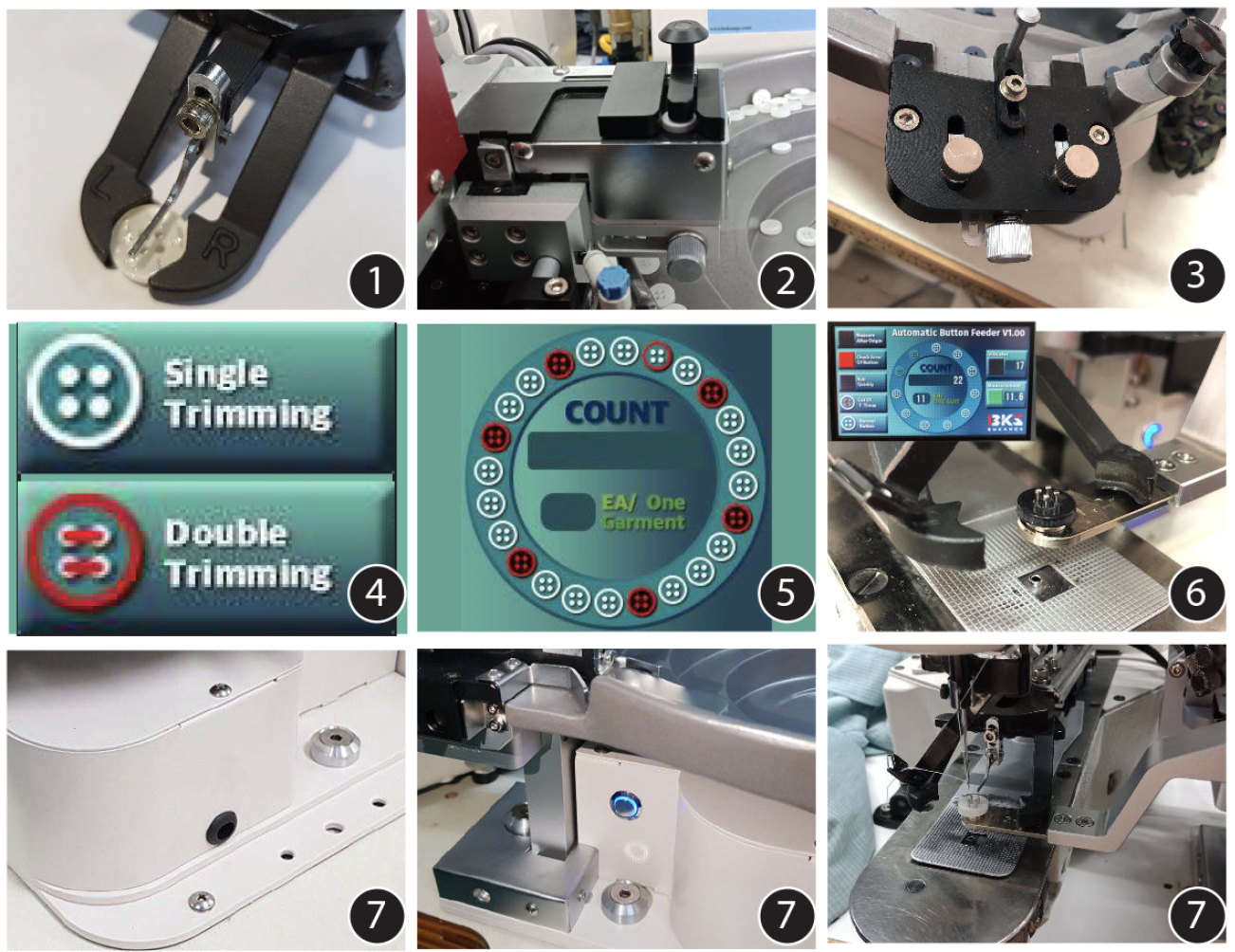

- One body type loosening clamp – automatic loosening clamp position so easy loading of button manually also

- Easy Button measure – easy button change, just one touch, one time can set button width and thickness together

- Eaasy Micro Adjustment – to control facing of button in-vibrator

- Two times cutting – can select after single or double trimming to supply button to work clamp

- Cyclic program – We can select the number of button patterns where we need regular button supply & whenever we dont need button supply so we can fix button manually

Point button – Can be programmed to load the other size button by hand - Supply button – Automatic button supply in absence of no button in work clamp

- X,Y adjustment – Easy to set the X & Y axis for transfer pin setting to needle

Extra:

- High quality SMC cylinders solenoid assembly used

- in shirts can achieve 1200 – 1650 * buttons per hour

- can installation any brand lockstitch button sewing machines

- easy installoation

- easy button change by one touch

- no need expert, any one can operate

- touch type display and easy volume controlling